In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.

Humans are great at finding meaning in a wide and diverse array of data. This is, in part, because we are very good at recognizing patterns. At first, a new experience can be overwhelming. Think about it from the perspective of a newborn baby (if you can). It’s no wonder they cry so much given the enormity of their experience! But over time, they find consistencies and patterns that make cognitive overload less overwhelming, more predictable, and manageable.

Those of us that do root cause analysis for a living also identify patterns that make our jobs easier, albeit with marginally less screaming and crying. Although we teach cause and effect analysis as being a process of deconstructing effects into their individual causes, that’s not always how we do it professionally. We often find that we’ve been down a certain path before. One of the benefits of building a cause and effect logic diagram is that it allows us to spool up similar past experiences in the form of generic “causal patterns.” These causal patterns are defined at a higher level of abstraction. They are not specific, but they provide the investigator with a starting point that can help speed up the root cause analysis while enhancing quality. So we thought it would be useful to publish some of our favorites. This list is by no means exhaustive. But it should be useful in a variety of applications, and will demonstrate the utility of cause patterns in general.

Spills

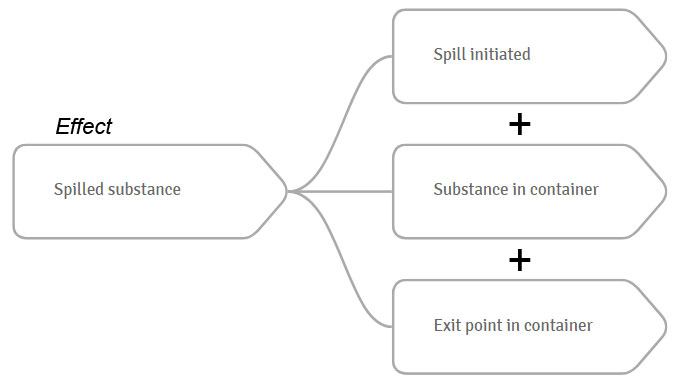

A spill can be defined as any form of primary containment loss. Examples include a cup of milk spilled by a toddler or a 50,000 gallon release of ammonia.

A spill can be defined as any form of primary containment loss. Examples include a cup of milk spilled by a toddler or a 50,000 gallon release of ammonia.

Most spills are caused by:

1. Spill Initiated: Upset container, opened valve, punctured container, or any other similar sort of initiating event. Note that there are some implied conditions. For instance, upsetting the container means that the container was sufficiently tipped to such a degree to allow the substance to overtop the edge of the container. A puncture will only result in a spill if it occurs below the level of substance in the container. The same is true with an opened valve – the inflow to the valve must be below the substance level. If required, these could be “decompressed” to show the more granular detail. Spill initiation can be a form of exceedance, described below. For instance when a cup tips to a certain angle before the liquid inside spills out. It can also be the result of impact, such as when a cup is impacted with sufficient force to upset the cup.

2. Substance in Container: In order to spill something, whatever it is must be present in the container.

3. Exit point in container: There must be a pathway from which the contents exit the container.

Damage

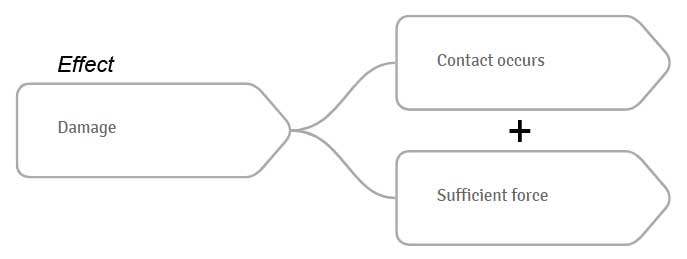

Damage can mean so many things, which is why this pattern is so useful. Anything broken (bones, glass, iPhone screen, etc.) is a form of damage. But also dents, scratches, sprains, strains, cuts are all forms of damage that result from contact along with enough force.

Damage can mean so many things, which is why this pattern is so useful. Anything broken (bones, glass, iPhone screen, etc.) is a form of damage. But also dents, scratches, sprains, strains, cuts are all forms of damage that result from contact along with enough force.Causes of most forms of damage are:

- Contact: Most forms of damage involve contact of some sort. Two cars hitting each other, a glass striking the ground, or a falling object hitting someone in the head – all are forms of contact.

- Sufficient force: Contact alone is not enough – you also need a sufficient amount of force in order to cause damage. For instance, a rain drop can fall for a thousands of feet from a cloud overhead, but do no damage when it hits you. A golf ball-sized hailstone, on the other hand, may knock you to the ground. The difference is the amount of force associated with the contact.

Exceedance

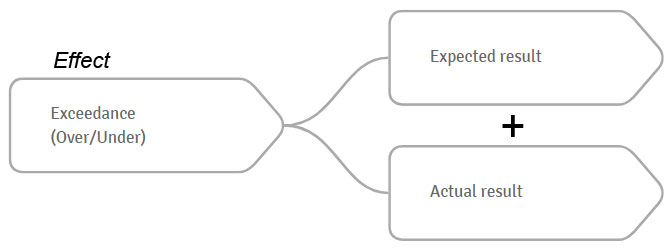

An exceedance is any value that surpasses a low and/or high acceptable value threshold. There are a great many events that fit the exceedance pattern. A product not made to specification, a deadline missed, a speed limit violation, too many people in an event hall... the list goes on and on. Note that “Sufficient Force” (discussed above) is a form of exceedance.

An exceedance is any value that surpasses a low and/or high acceptable value threshold. There are a great many events that fit the exceedance pattern. A product not made to specification, a deadline missed, a speed limit violation, too many people in an event hall... the list goes on and on. Note that “Sufficient Force” (discussed above) is a form of exceedance.Causes of most types of exceedances:

- Expected result: This can be a scheduled meeting start time, a mill specification, a preventive maintenance due date, a desired weight, a deadline, a desired delivery date, etc.

- Actual value: This is the actual value, such as actual meeting start time, actual part dimension, when the preventive maintenance activity was performed, the actual weight, the actual delivery date, etc.

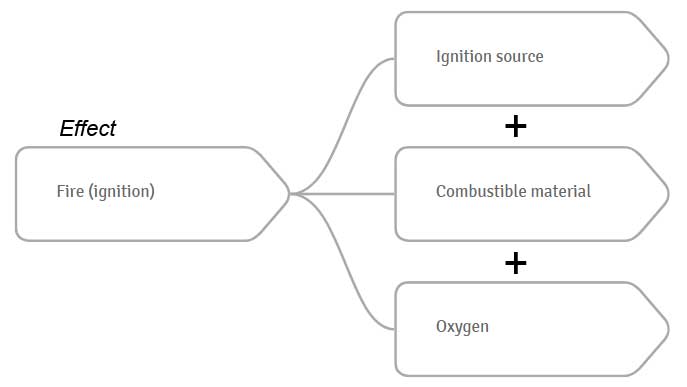

Fire (at Ignition)

Fires at ignition require an ignition source able to exceed the autoignition temperature, combustible material, and oxygen. Note that the ignition source is a form of exceedance.

Fires at ignition require an ignition source able to exceed the autoignition temperature, combustible material, and oxygen. Note that the ignition source is a form of exceedance.Fire (Continuous):

Fires that continue to burn require combustible material, oxygen, and need to maintain a temperature greater than the autoignition temperature of the material.

Causes of most fires:

- Ignition source: A match strike, contact with an existing heat source, a static spark (completed circuit -described above) are all types of ignition.

- Combustible material: That’s what burns. Well, as was explained to me recently during a fire investigation, gasses that are produced by heat are what actually burn, but you get the idea.

- Oxygen: Most fires require a source of oxygen. Often this is just the atmosphere, but if a fire occurs in an environment that is supposed to be inert, this pathway becomes very valuable.

Human Error

Human error is a huge subject. But most errors can be understood via this pattern. A person takes action. They do this based on some form of a plan. And they must execute that plan successfully. If either the plan or the execution is substandard or in error, the result will be an error.

Human error is a huge subject. But most errors can be understood via this pattern. A person takes action. They do this based on some form of a plan. And they must execute that plan successfully. If either the plan or the execution is substandard or in error, the result will be an error. Causes of most errors:

- Person took action: The possibilities are endless, but let’s say they initiated forklift activity to move a pallet of product from the production area to the finished goods area.

- Plan was Faulty: People take action for a reason, such as to move product that has been completed from the production area to the finished goods area. But if their plan omitted checking with the operators in charge of production prior to moving product, then there was a gap in the plan. They may have successfully executed the move – but the result was not what they intended.

AND/OR - Execution was Faulty: Same example as above, but this time the product was complete and ready to be moved, but the forklift driver ran into a wall and destroyed all the finished goods on the pallet. Oops. In this case, the plan was fine – but the execution broke down.

Note that sometimes it’s both! So many RCAs stop once they find an error, but this is always a mistake (an error!). Humans commit errors, particularly if the work is complex or if they are new on the job. If we are going to reduce the occurrence of errors, we need to understand the precursors to the error. This pattern allows us to do that.

Learning to use causal patterns – alone or in combination – is a great way to very quickly move through a cause and effect analysis while enhancing it’s quality/completeness. Please remember that these patterns offer an initial starting point – they often need to be adjusted to fit specific events. But doing so only adds to your value as an investigator because you will be able to draw upon these experiences to enhance future investigations.

Learn more about Sologic RCA

In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.