In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.

Our world is overwhelmingly complicated. One tactic for managing complexity is to group similar things together. This allows us to draw one broad set of conclusions about the group rather than each individual member.

The process of grouping like things together is called Categorization. Categorization works through the logic of sets. A category is essentially a label that describes a common set of fundamental attributes. For instance, we could create a category called “Adult” and apply it to a stadium full of people. If by adult, we mean humans that are 18 years old or older, we can then easily divide the people in the stadium up into two sets. We can then draw certain conclusions about all members of each set based on the definition of the category. For instance, adults in the USA are presumed to be mature enough to vote or serve in the military. In this way, categorization helps manage complexity because it allows us to cut through many of the unique attributes and details of every individual and draw simpler, categorical conclusions.

The process of grouping like things together is called Categorization. Categorization works through the logic of sets. A category is essentially a label that describes a common set of fundamental attributes. For instance, we could create a category called “Adult” and apply it to a stadium full of people. If by adult, we mean humans that are 18 years old or older, we can then easily divide the people in the stadium up into two sets. We can then draw certain conclusions about all members of each set based on the definition of the category. For instance, adults in the USA are presumed to be mature enough to vote or serve in the military. In this way, categorization helps manage complexity because it allows us to cut through many of the unique attributes and details of every individual and draw simpler, categorical conclusions.

One problem with a broadly defined category (such as adult) is that it is not very precise. Is it true that everyone 18 or older is qualified to vote or join the military? Maybe, but not always.

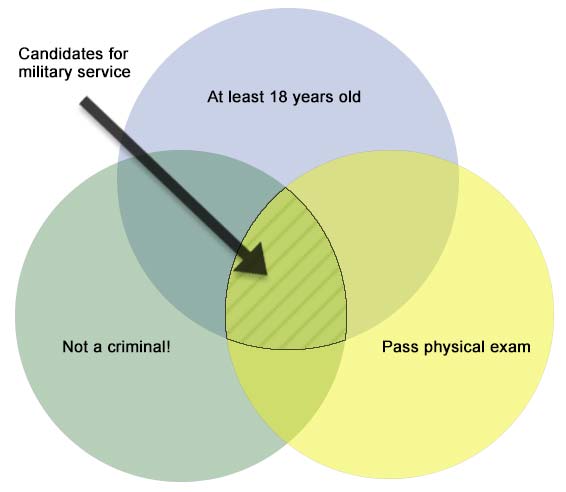

In order to make categories more precise, we refine them. For instance, to better identify candidates for the military, we could further subdivide everyone in our imaginary stadium like this:

1. Humans at least 18 years old

a. Pass physical exam

i. No serious criminal background

This provides a more granular cut from the original population of the stadium. You can see how it makes it much easier to manage the complexity of deciding who in the stadium might be qualified to serve in the military. There are additional qualifications for joining the military, but hopefully this example helps illustrate the point.

Let’s bring the conversation around to structured problem-solving. Structured problem-solving can certainly benefit from the application of categorical logic, but we need to be aware of the risks of generalization and inconsistent application. For example:

“At 4:45AM a maintenance team began reviewing preventive maintenance tasks for the 2-hour daily downtime window that occurs between 5am – 7am. They consulted with the maintenance management system to review the list of tasks. One of those tasks was to change out a belt connecting a motor to a gearbox. It seemed simple enough, but when the team was about to perform the task, a supervisor walking by noticed that they had failed to properly tag out the electrical source. The lock was present, but the tag was missing. The supervisor halted the work, instructed the team to fill out the tag, and then documented the incident. The team was given a written warning. The next morning, the incident was reviewed in front of the entire maintenance staff.”

There are a lot of things going on here, but the urge to boil it down to a simple case of “human error” (a categorical label) is nearly irresistible. Imagine if you were relaying this story to someone unfamiliar with it. Would you be more likely to explain all the relevant details and nuances or just keep it simple?

The answer depends on your audience, but simple usually wins. As problem-solvers we need to move past generalities and get into the details. How do we solve “human error” without knowing the causal precursors to the error? Categories derive their usefulness from being non-specific. However, confusing categories with causes can be detrimental to the process of problem-solving because it’s simply impossible to “solve” a category.

Categorical logic can be very useful though. Consider the process of gathering data. When investigating, we seek data and evidence from a variety of sources. Those sources include People, Process/Procedures, Hardware/Software/Systems, and Environment.

Using these categories to gather information is helpful. In fact, the classic Ishikawa fishbone diagram uses similar categories in this way and, even though at Sologic we do not find either the Ishikawa diagram or the process of voting on root causes to be effective, we do like how the categories prompt us to look for causes in different places.

Categorical logic is also useful in reporting. Pareto charts and Venn diagrams function via the logic of sets. These kinds of reporting mechanisms allow us to more easily draw conclusions from larger sets of data. Of course, we need to be careful to consistently assign categories or risk drawing conclusions or making decisions based upon inaccurate data. But, when steps are taken to ensure consistency, these types of reports can be invaluable management tools.

Next up, we will discuss Conditional logic and how it is useful in solving problems in a structured way.

Learn more about Sologic RCA

In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.