In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.

We are excited to announce a new upgrade to Causelink Root Cause Analysis (RCA) software. Causelink version 6.0 makes problem-solving easier with a new 5Whys+ RCA template. The template combines the ease of the 5 Whys method with the analytical power of Sologic’s cause & effect charting; all on a simple, one-page interface.

Since Sologic is known for its robust RCA method and 5 Whys is a competing, bare-bones method, some customers have been asking “What’s up?” This post will fill you in.

Causelink customers from a variety of industries have requested a simple RCA approach for moderate impact incidents; ones that don’t require the rigor of a Sologic RCA. Initially, our response went something like “Just use Causelink and skip the sections that you don’t need”. People have generally made this work. But, when you are tasked with an RCA and focused on analyzing the incident, the last thing you want is to click through un-needed pages. We decided to take this feedback as an opportunity to make Causelink even better– enter the 5Whys+ template.

The traditional 5 Whys method offers a simple, fast analysis for problems of small to moderate complexity – ask why five times to develop a deeper understanding of the problem. But it can be misleading, and most practitioners are at least a little frustrated by its limitations. Our new 5Whys+ template keeps it simple, but also offers the ability to build a detailed cause and effect model when needed – hence the “+”.

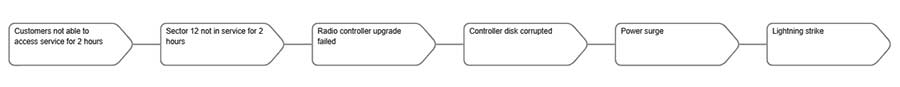

For example, a traditional 5 Whys analysis might look something like this:

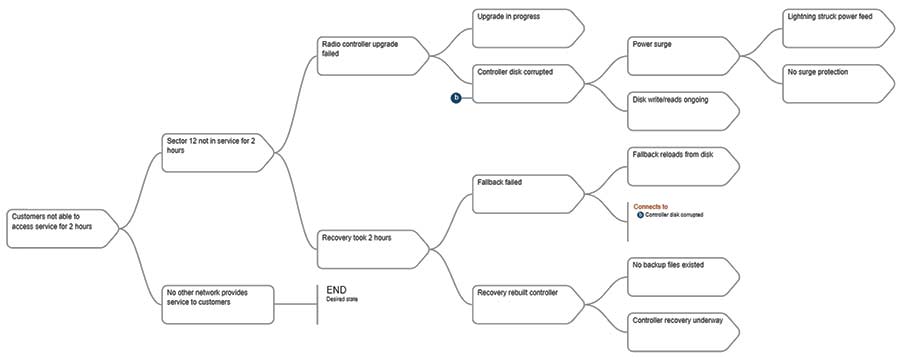

With 5Whys+ you can add details to gain a better understanding of the problem, like this:

The new template also provides a simple way to define the problem, assign corrective and preventative actions, and produce a final report. The basic needs of an RCA are supported on one simple page. When more complex problems arise, switch to the Sologic template and dive deeper into the analysis. The best of both worlds, right? We believe so.

In addition to the 5Whys+ template, this upgrade adds improvements to the cause & effect engine, a new tags feature, and the ability to integrate with data visualization tools like MS Power BI and Tableau. These new features bring a ton of benefits to RCA teams:

- Complete records faster. With everything on one page and design improvements to the cause & effect engine, you’ll get work done faster.

- Faster work and better user experience lead to more investigations of a higher standard. Your data becomes more meaningful in common cause reports, trend analysis, risk management, corporate memory, etc.

- With an easy interface, more people will feel comfortable using the system; even those new to 5 Whys or Sologic RCA. When more people complete RCAs, you get greater visibility and a better understanding of the problems in your organization.

- With one simple page, the new template removes traditional barriers and excuses for not doing structured problem solving (takes too long, costs too much, We're too busy, it’s too complicated)

5 Whys Root Cause Analysis Problem

What is the 5-Whys Root Cause Analysis Process?

The 5-Whys method is about as simple as its name suggests: Ask why five times, and you’ll likely arrive at the root cause. It utilizes conditional if/then logic.

It was originally used at Toyota as a way to help line workers drill deeper into production issues. The goal is to drive past symptoms to get into the underlying causes. Addressing these causes will be more likely to ensure the problem does not happen again.

But why five whys? Why not four or six? The name is not meant to be taken literally, although it often is. By providing a fixed number (five), it eliminates what would otherwise be ambiguous interpretations.

How Do You Use the 5-Whys Root Cause Analysis Method?

The 5-Whys method is based on the simple rule of conditional logic that follows the pattern “If..., Then...”

For instance, if I knock over my cup of tea, then the tea will spill. And its opposite is also true: If I don’t knock over my cup of tea, it will not spill.

But the 5-Whys takes it further than that, identifying precedents to each cause. By looking at preceding causes, the 5-Whys introduces time into the model. The introduction of time is a fundamental difference between the 5-whys and Fishbone models (link?). The underlying premise is if you go backward in time to uncover preceding causes, you will eventually find the “root cause.” If you control the “root cause,” then you solve the problem.

What are the Benefits of 5-Whys Process?

The 5-Whys is easy - anyone can use it or explain it. The 5-Whys helps teams quickly drill into the underlying causes of a problem. And the 5-Whys is helpful. By examining precursors, the 5-Whys improves understanding and the process of identifying a solution.

What are the Drawbacks to the 5 Whys Process?

The 5-Whys is overly simplistic. Because it does not take into account that causes often work together, it typically does not identify complete causal relationships. Also, it tends to focus mostly on causes associated with people while leaving many of the other necessary causes unaddressed.

Does Sologic Use the 5-Whys?

The Sologic method utilizes the conditional if/then logic of the 5-Whys method, but with some important modifications. First, we eliminate the arbitrary need to drill five levels deep. And second, we add AND/OR logic to the diagram, similar to what would be found in a Fault Tree Analysis.

Learn more about Root Cause Analysis Training

In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.