In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.

I’m sure you've experienced the strong sense of euphoria often felt after starting a new relationship. You can’t stop thinking about this new person and they help fill your world with a kaleidoscope of sounds and colors. You can’t imagine yourself being happy with anyone else. Well, I’m feeling that way about Causelink Enterprise Version 4.0! Here’s why:

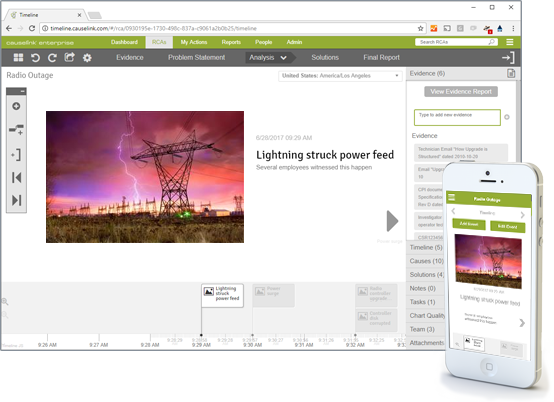

First off, the new design! We came up with a new RCA interface in early 2017 during a design brainstorming session for a different feature. We had wanted to create a “Wizardly Wizard” that would guide you through the major steps in a root cause analysis: Gather evidence > Define the problem > Analyze cause & effect > Identify solutions > and Final report. We spent days architecting each screen and describing the options we’d make available. But then it hit me – Why put this in a Wizard? Why not turn the main navigation into the major steps in an investigation? I’m not sure why it took years to ask these questions, but I’m really glad that we did. I’m so proud of this new interface and how much better it will be for the people using Causelink. The new design has been up in our dev environment for 3 months and I still pull Causelink up in my browser just to see how beautiful it is.

Another cool thing about the new design is that the change is backed up with data. Our analytics reporting tells us that people use Evidence, Problem Statement, Chart, Solutions, and Report more than any other page in Causelink (Timeline isn’t live yet – more on that soon). It also shows that those sections of the application contain more data than any other section. Since people like these pages more, we’re making them even easier to use. Makes sense, right?

Secondly, after hearing the feature request from many customers in a variety of industries, we’re pleased to enable an Incident Timeline within Causelink. One thing that made this feature a success, in addition to having a top-shelf development team, is that we had great participation from a diverse group of Beta testers. How closely should we integrate the Timeline with the Chart? How can we account for gaps in time when creating a Timeline PDF? How granular do we need to get with time definition – are milliseconds enough? All these questions and more were answered during Beta testing and we’re extremely pleased to be offering this new, highly useful feature.

Why is it useful? Depending on the incident and the investigation team, it can often be easier to start an analysis with a linear timeline. X happened and then Y happened, and then Z… Once you have that level of understanding, you can flip those events around and have a great start to your cause and effect chart. Causelink does this for you automatically. Also, when you make a Timeline PDF, it allows you to communicate your findings in an easy format and helps others understand the complexity of the problem you are investigating.

Finally, I love Causelink v4.0 because of the usability improvements. We didn’t initially plan for them, but in the first part of 2017 it became obvious that we needed to make some changes. I was traveling with our Senior VP, Brian Hughes, to talk with customers about how they were using Causelink and what features they would like to see in the future. We were fortunate enough to be on hand during a number of facilitations where Causelink was put to use. For a VP of Product, who is always looking for improvement ideas, I couldn’t have asked for anything more than face time with customers using our product. There were many great ideas that came from these meetings, but the best improvement involved the cause and effect chart. I watched a young, very smart Engineer struggle with dragging and dropping causes on a large chart. When I asked what would make this better she said “Why can’t I click to drag and double-click to edit?”. Again, I’m not sure why we didn’t think of that years ago, but we’re all happy that it’s now included in Causelink v4.0. After I got back to the office and met with our developers, it took 2 hours to see the change made in our development environment. It’s so much better, I’d say the entire customer visit was paid for right there!

There’s so much more I could write about, but suffice it to say there are a ton of great improvements and features wrapped up in Causelink Enterprise v4.0. As can happen in relationships, I imagine the euphoria I feel about v4.0 will fade with time. But that will only happen as we start planning for Causelink v5.0!

Learn more about Sologic RCA

In the dynamic landscape of business operations, the pursuit of excellence is a perpetual journey. One of the fundamental tools in this journey is Root Cause Analysis (RCA), a systematic process for identifying the underlying causes of problems or incidents within an organization. But what exactly is RCA, and how does it intersect with the broader concept of Continuous Improvement?

Understanding Root Cause Analysis (RCA)

RCA is a structured approach aimed at uncovering the root causes behind undesirable events or issues. It goes beyond addressing symptoms to delve into the underlying factors that contribute to a problem's occurrence. RCA typically involves several steps, including problem identification, data collection, analysis, identifying root causes, and implementing corrective actions to prevent recurrence.

Continuous Improvement: A Culture of Progress

Continuous Improvement is a philosophy focused on making incremental enhancements to processes, products, or services over time. It entails an ongoing commitment to innovation, efficiency, and effectiveness within an organization. Continuous Improvement fosters a culture where every individual is empowered to identify areas for improvement and contribute to positive change.

Correlating RCA with Continuous Improvement

RCA and Continuous Improvement are intertwined in their pursuit of organizational excellence. RCA serves as a crucial tool within the framework of Continuous Improvement by pinpointing areas ripe for enhancement. By systematically identifying and addressing root causes of problems, RCA provides valuable insights that fuel the Continuous Improvement engine. For instance, if a manufacturing facility experiences recurrent equipment failures leading to downtime, conducting an RCA can uncover underlying issues such as inadequate maintenance procedures or substandard equipment quality. Addressing these root causes not only resolves immediate concerns but also lays the groundwork for long-term process enhancements.

Key Benefits of RCA to Continuous Improvement

- Preventive Action: By identifying and addressing root causes, RCA helps prevent the recurrence of problems, leading to more stable and reliable processes.

- Data-Driven Decision Making: RCA relies on data and evidence to drive insights, enabling informed decision-making in the pursuit of Continuous Improvement.

- Enhanced Efficiency: By streamlining processes and eliminating inefficiencies, RCA contributes to overall operational efficiency and productivity gains.

- Cultural Shift: Implementing RCA fosters a culture of accountability and learning within an organization, where continuous learning and improvement become ingrained values.

- Customer Satisfaction: Continuous Improvement fueled by RCA results in higher quality products or services, ultimately leading to increased customer satisfaction and loyalty.

In conclusion, Root Cause Analysis is a linchpin in the broader strategy of Continuous Improvement, providing organizations with the insights and tools needed to drive sustainable growth and excellence. By integrating RCA into their operations, businesses can unlock the full potential of Continuous Improvement and embark on a journey of ongoing advancement and success.